#4 Blog

Life-Cycle Impact Assessment of Carbonated Recycled Concrete Aggregate: A Sustainable Pathway

September 2023 - Romain Sacchi, Andreas Leeman, Christian Bauer

In the first blog post (see post #1), Johannes Tiefenthaler gave us some insights on the carbonated Recycled Concrete Aggregate (RCA) supply chain operated by Neustark. In a second blog post (see post #2), the dedicated research team of Andreas Leemann and Frank Winnefeld at Empa described the microstructural change in concrete when using RCA. This post will delve deeper into the environmental life-cycle impact assessment (LCA) of accelerated CO2 mineralization in RCA as it is executed by Neustark. This blog post aims to provide a comprehensive understanding of the system boundaries and, most importantly, reveal the potential for 1) removing CO2 from the atmosphere via accelerated CO2 mineralization, and 2) reducing greenhouse gas (GHG) emissions via reduced virgin material sourcing.

What do we want to know?

Life-cycle assessment is an emissions accounting method that evaluates the environmental impacts of all the relevant stages of a product or service’s life-cycle: production, use and discard. This accounting method is specifically relevant to Carbon Dioxide Removal technologies (CDR), such as mineralization of CO2 in recycled concrete aggregate. Indeed, it allows us to compare the amount of emissions occurring along the supply chain of CO2 mineralization in RCA (e.g., electricity generation, transport, crushing, etc.) with the amount of CO2 mineralized. In DemoUpCARMA, we specifically aim to proof that the former is inferior to the latter and that the whole operation does result in a net removal of CO2 from the atmosphere.

Understanding the system boundaries and analysed production processes

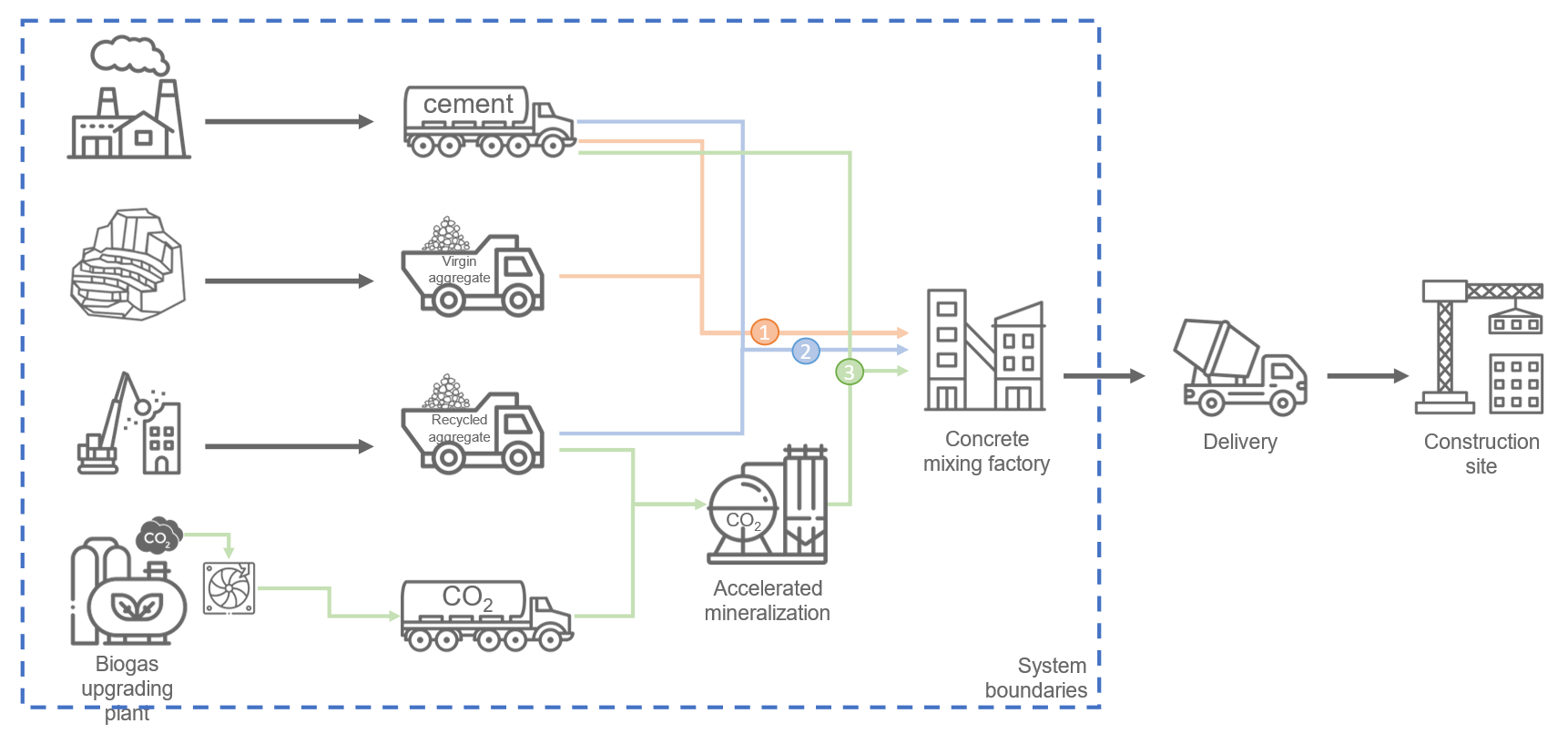

In a first step, our analysis establishes the system boundaries for the LCA – boundaries within which emissions of the supply chain are accounted for. These boundaries ensure a basis for comparison with similar supply chains. The LCA of carbonated RCA starts with the demolition of existing concrete structures, followed by the process of crushing and transporting the demolition waste to the concrete production plant. The RCA then undergoes carbonation at the plant, where biogenic CO2 captured from a biogas upgrading plant (i.e., initially removed from the atmosphere through biomass photosynthesis) is mineralized by reacting with old cement paste contained in the RCA (i.e., “carbonation”).

In the following steps, different production routes for concrete production are analyzed and compared. First, we look at the production of concrete using natural aggregate and Portland cement (= classic cement) (see number 1 in Figure 1, orange arrows). The environmental performance of this route – for example, in terms of climate impacts – is compared with concrete production using RCA (number 2 in Figure 1, blue arrows) and carbonated RCA (number 3 in Figure 1, green arrows). Subsequent steps, including the concrete transport to the construction site and application in the new structure, are excluded from the system since they do not differ whether RCA (carbonated or not) is used.

Figure 1: System boundaries of the three pathways considered: concrete production with 1) cement + virgin aggregate (orange arrows), 2) cement + recycled aggregate (blue arrows), and 3) cement + recycled carbonated aggregate (green arrows). Delivery and use of concrete are out of scope. While all relevant activities and services are considered, they are not all represented in this figure (e.g., provision of electricity).

Concrete designs

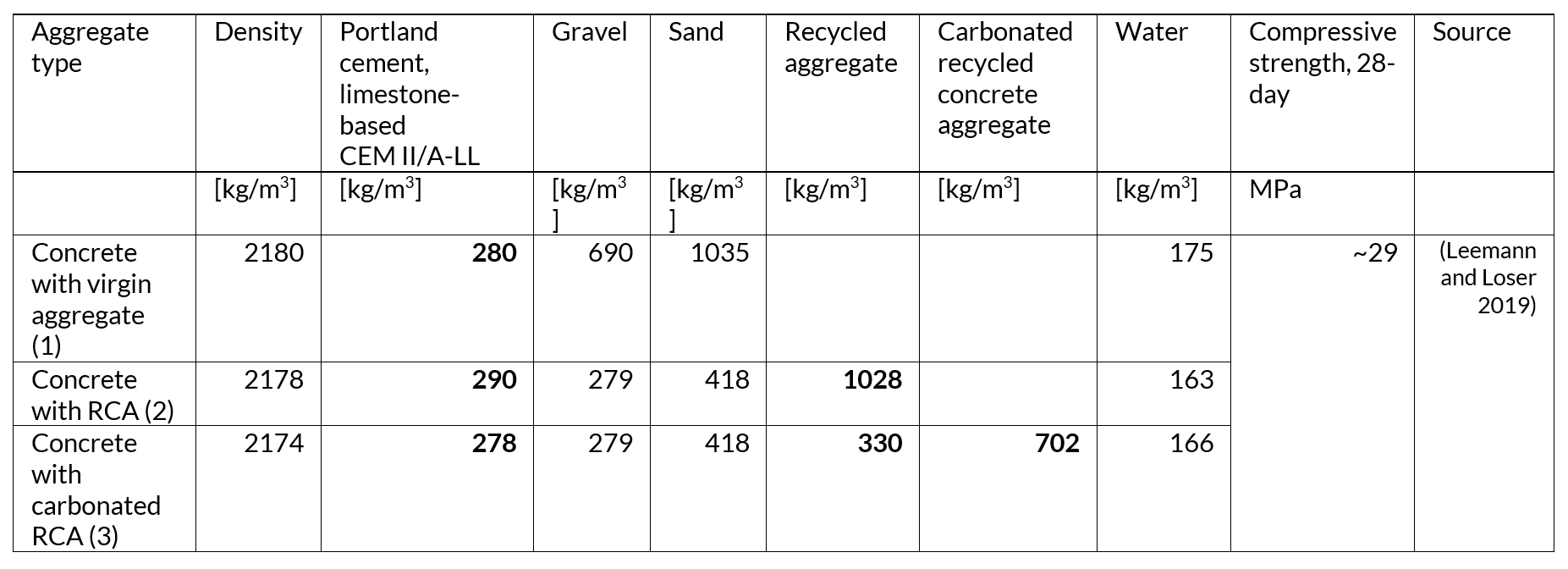

As explained in detail in blog post #2, the decalcified calcium-silicate-hydrate (C-S-H) phase observed in carbonated RCA after the CO2 mineralization step results in increased compressive strength of the concrete, which allows using less cement at an equal compressive strength level compared to using uncarbonated RCA. The concrete mix designs corresponding to the three options considered are presented in Table 1.

Table 1: Concrete recipes for options 1 to 3. All three concrete recipes reach a 28-day compressive strength of 29 MPa. The cement use increases when replacing virgin aggregate with RCA. However, using carbonated RCA allows using less cement compared to uncarbonated RCA. The cement content when using virgin aggregate and carbonated RCA is approximately the same.

Results

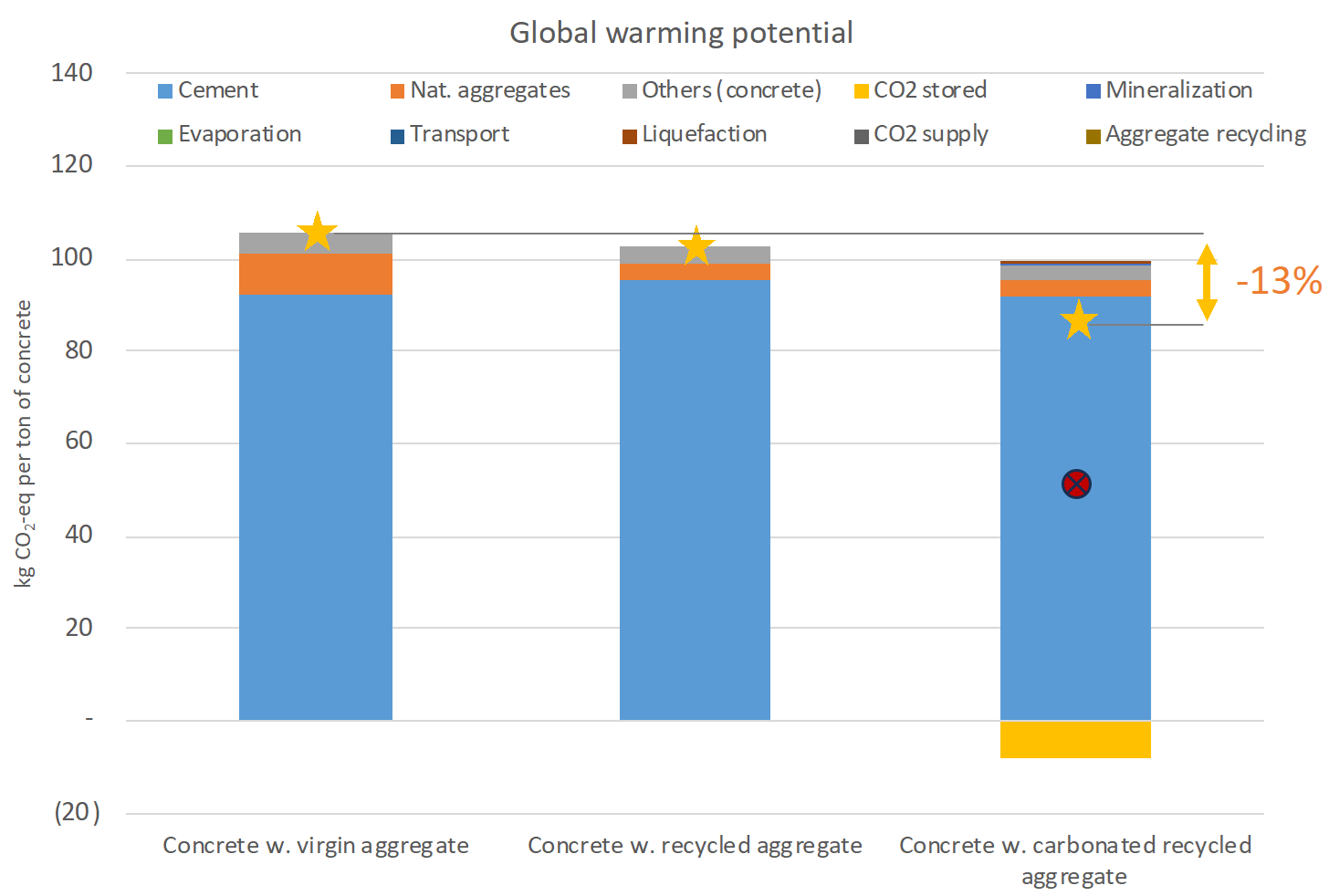

The figure below shows the Global Warming Potential (in kg CO2-eq.) per ton of concrete produced for the three options: concrete with virgin aggregate, concrete with RCA and concrete with carbonated RCA.

Simply switching from virgin to RCA (first two bars in Figure 2) does not deliver significant GHG emissions reduction: the GHG emissions reduction due to sourcing (i.e., demolition, crushing, transport) recycled aggregate instead of virgin aggregate is unfortunately compensated by increased use of cement to maintain the same compressive strength.

However, the use of carbonated RCA reduces the contribution of concrete production to climate change, compared to using virgin aggregate and uncarbonated RCA. Compared with using virgin aggregate, the net-reduction in global warming potential is 13%. Note that this result is mostly sensitive to the carbon intensity of the electricity used (see next section). Two-thirds of that net-effect comes from the ability of RCA to absorb CO2 , removing CO2 from the atmosphere. The remaining third comes from less GHG emissions associated to sourcing recycled aggregate compared to sourcing virgin aggregate. When compared to using uncarbonated RCA, the net-reduction in global warming potential is about 9%. Similarly, two-thirds of the net-effect comes from CO2 mineralization, i.e., carbon removal, and the remaining third comes from the reduced cement use thanks to the reaction between newly formed portlandite and C-S-H and cement, i.e., GHG emissions reduction. As elaborated in blog post #2 and shown in the table above, the cement content of the mix design using carbonated RCA could be reduced by 5 – 7 % compared to using uncarbonated RCA. Given that cement production is a significant source of CO2 emissions, any reduction in its usage has a positive effect (i.e., emissions reduction) and decreases the environmental footprint of concrete.

Figure 2: Global Warming Potential impact per ton of concrete, considering the warming potential of emitted gases over a 100-year time horizon. The yellow star indicates the net sum of GHG emissions. The red dot indicates the amount of GHG emission emitted per 1'000 kg of CO2 abated.

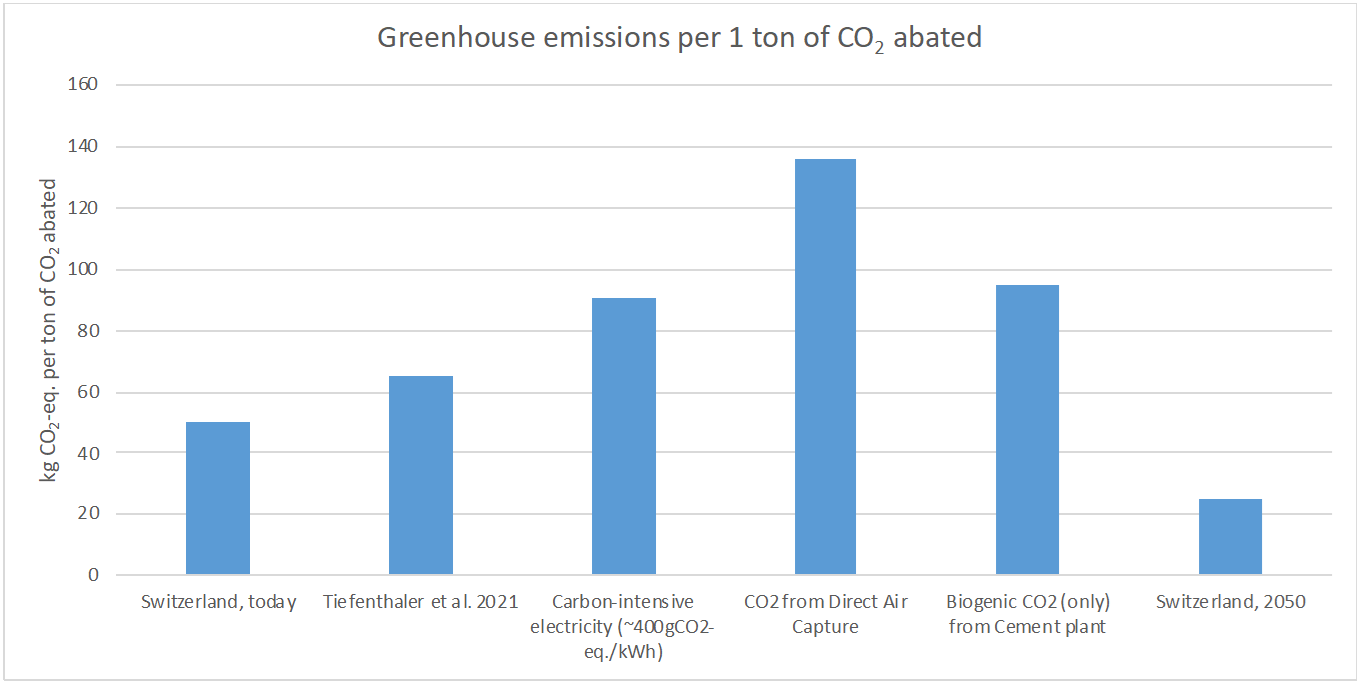

CO2 abatement efficiency of CO2 mineralization in old concrete aggregate

Another way to look at it is to consider the additional amount of GHG emissions the concrete supply chain emits when using carbonated RCA to abate 1 ton of CO2-eq. (i.e., considering removal and reduction), which can be referred to as the CO2 abatement efficiency. In other words, let’s consider only the net difference in emissions with the reference case, necessary to abate 1 ton of CO2-eq. The red dot in Figure 2 indicates that approximately 50 kg of CO2-eq. is emitted while abating 1 ton of CO2-eq. This number is also represented in Figure 3, under “Switzerland, today”. It may be lower or higher depending on the specific supply chain considered. For example, if the electricity used to capture, liquefy, and evaporate the CO2 is carbon-intensive (based on fossil energy), it may cause almost 100 kg of CO2-eq. emissions per ton of CO2 abated, as also shown in Figure 3. By 2050, thanks to continued effort to decarbonize the electricity supply, this amount may reduce to ~20 kg of CO2-eq., meaning the CO2 abatement efficiency may reach nearly 98%.

Figure 3: Greenhouse gas emitted per ton of CO2 abated. "Switzerland today" = reference case (biogenic CO2 from biogas plant, electricity @ 128g CO2-eq./kWh). "Switzerland 2050" = biogenic CO2 from biogas plant, electricity @ ~45g CO2-eq./kWh (from Energy Perspectives 2050+, Business-as-usual scenario). (Tiefenthaler et al. 2021) refers to a study considering a similar supply chain that omits the strength increase resulting from Portlandite and CO2 reaction.

In conclusion, our life-cycle assessment reveals that using carbonated RCA helps reducing the contribution of concrete production to climate change. Together with the adoption of other equally effective measures (e.g., use of alternative supplementary cementitious materials to reduce clinker requirement in the concrete, reduced use of concrete via design optimization of buildings), the use of carbonated RCA opens the door to reducing CO2 emissions from the construction industry, which still represents a quarter of the national GHG emissions today (BAFU 2023). By exploiting the beneficial properties of carbonated RCA, we can help a hard-to-abate sector that needs rapid decarbonization and simultaneously roll out a domestic carbon dioxide removal technology. This technology is however subject to one constraint, which is that of the availability of RCA. Also, from an environmental viewpoint, this technology makes most sense when operated with low-carbon electricity and non-fossil CO2.

Authors

Romain Sacchi and Christian Bauer are researchers at the Technology Assessment Group at the Paul Scherrer Institute.

Andreas Leemann is group leader for Concrete Technology at Empa.

References

BAFU. 2023. “Buildings.” 2023. bafu.admin.ch/bafu/en/home/topics/climate/info-specialists/reduction-measures/buildings.html.

Leemann, Andreas, and Roman Loser. 2019. “Carbonation Resistance of Recycled Aggregate Concrete.” Construction and Building Materials 204: 335–41. doi.org/10.1016.

Tiefenthaler, Johannes, Lisa Braune, Christian Bauer, Romain Sacchi, and Marco Mazzotti. 2021. “Technological Demonstration and Life Cycle Assessment of a Negative Emission Value Chain in the Swiss Concrete Sector.” Frontiers in Climate 3. doi.org/10.3389.