WP2: Demonstration of CO2 utilization and storage in concrete (domestic solutions, CCUS)

Leader: Neustark

Participants: Neustark, Empa, Kästli, Ara Region Bern, PSI

The objectives of this work package are:

- Demonstrate the technical feasibility of a mineral carbonation value chain using and permanently storing CO2 in (1) recycled concrete aggregate (RCA) and (2) in concrete mixing water.

- Demonstrate the integration in the concrete manufacturing plant of a brand-new carbonation technique based on using siloes instead of containers thus enabling easier operation and higher extent of carbonation.

- Develop an understanding of the carbonation of RCA and concrete mixing water to allow the optimization of concrete mix designs in terms of energy efficiency and environmental performance by performing rigorous Life Cycle Assessment (LCA).

- Operate and validate the overall value chain at TRL 7/TRL 8 in collaboration with concrete manufacturing plants, using and storing overall 500 t of CO2 over the course of 15 months.

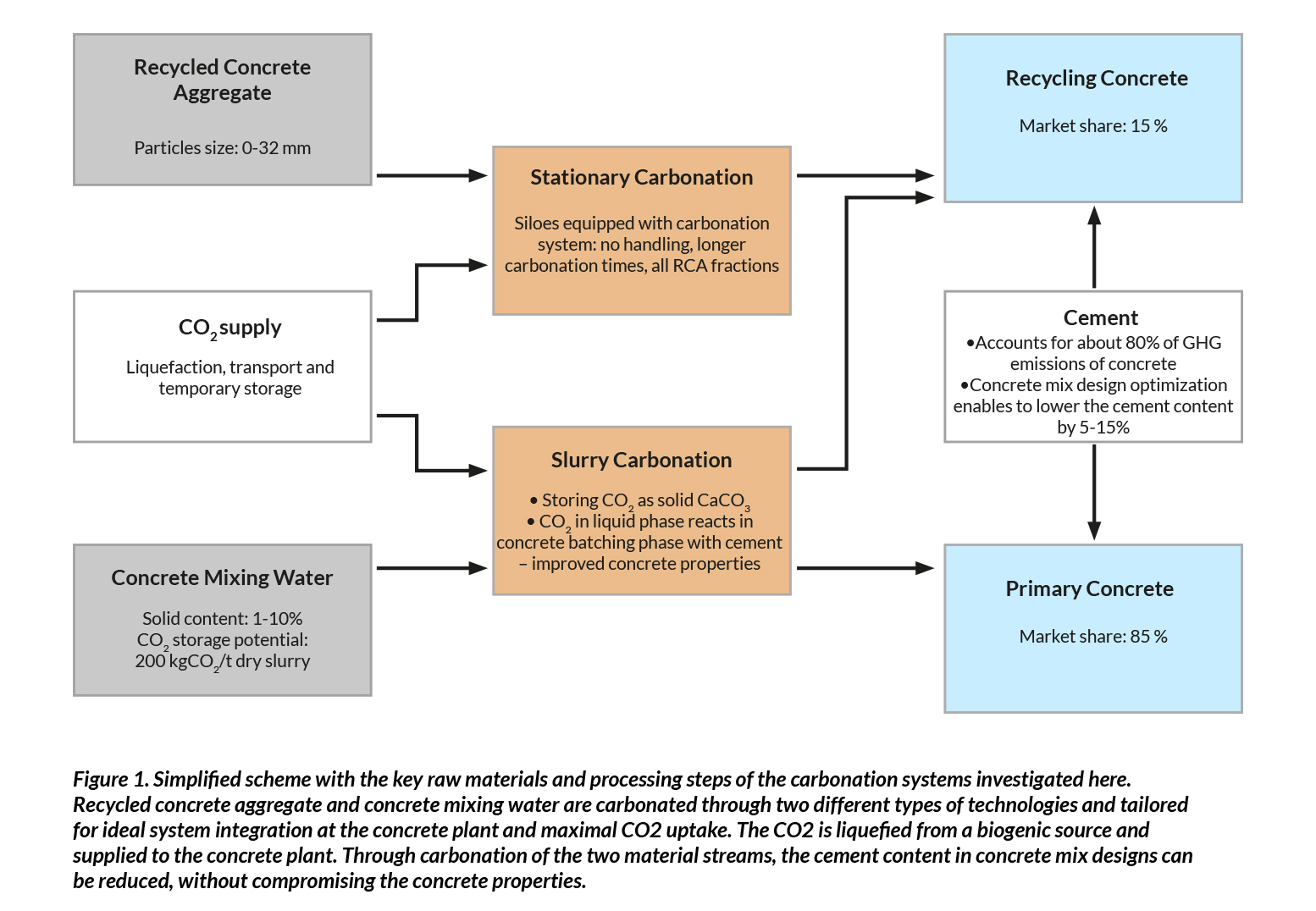

This work package aims at demonstrating a mineral carbonation system, which allows to (1) store CO2 permanently in both primary and recycling concrete, and (2) reduce the energy demand and GHG emissions associated with both types of concrete considering the entire value chain.

This WP builds on the learnings acquired in the RECARB project, where only a part of the full system proposed here was demonstrated for seven days at scale, i.e., the mineral carbonation of fine RCA with particles size up to 16 mm. Beyond that, an experimental proof of concept material study revealed, that carbonation has the potential to alter the material properties of RCA in such a way, that cement contents in concrete mix designs can be reduced to the regulatory minimum. Since cement is responsible for more than 80% of the energy demand and GHG emissions of concrete, this approach has the potential to reduce both the energy demand and the GHG emission of future concrete significantly. To facilitate the dissemination of this knowhow and enable the Swiss industry to apply it, a more comprehensive approach is necessary.

Based on the findings of RECARB, several aspects have been identified which require further attention to increase the maturity of the value chain, to improve its environmental end economic performance and thus enable a rapid knowledge transfer and decarbonization of the Swiss concrete sector:

- Maximize CO2 storage capacity per concrete plant and improve system integration of carbonation technology: The amount of CO2 stored at one concrete recycling plant is directly proportional to the economic and environmental performance of the value chain. In the scope of this project, the CO2 storage capacity is increased by extending the application of the carbonation technology to additional raw materials used for concrete manufacturing that can store CO2, namely RCA with particles size between 16-32 mm and concrete mixing water. Therefore, CO2 will be used and permanently stored not only in recycling concrete (as demonstrated in the RECARB project), accounting for 15% of the Swiss concrete market, but also in primary concrete, accounting for the remaining share of the market, see Figure 1. Moreover, the level of system integration of the RCA carbonation will be advanced, by retrofitting existing RCA silos with carbonation systems. This measure extends the carbonation time – thus larger amounts of CO2 can be permanently fixed, and it reduces the handling efforts.

- Environmental optimization of concrete mix designs: In the short term, there is the potential to reduce the carbon footprint and increase the energy efficiency of concrete mix designs on average by 5-10% with respect to state-of-the-art concrete mix designs. This can be achieved by a rigorous environmental optimization of concrete mix designs. Thus, primary and recycling concrete mix designs will be developed under the constraint to meet current norms for concrete (SN EN 206), and to bring the associated energy demand and carbon footprint down to the minimum. These tests will be accompanied by a LCA considering the entire material and energy supply chains, process emissions, and waste treatment (as the CO2 source) to assess the decrease in energy demand and carbon footprint. This LCA will also quantify the extent to which the concrete mix pathways will be able to act as permanent carbon sinks or so-called “negative emission technologies” (i.e., permanent removal of the CO2 from the atmosphere).

- Long-term demonstration of value chain: A 15 month long operation of the overall value chain will improve the technological maturity and enable the stakeholders to develop and test various business models.

To sum up, the work package addresses the key environmental, economic and technological challenges by storing CO2 in all size fractions of RCA and concrete mixing water (i.e., scope expansion), by developing and demonstrating mix designs optimized in respect with their carbon footprint and a long-term demonstration of the technology.

Tasks

Task 1:

Design, construction, and start-up of integrated mineral carbonation technologies

(Neustark, Kästli) (Month 1-6)

Task 2:

Development of low-carbon footprint concrete mix designs

(Empa, Kästli, Neustark) (Month 1-24)

Task 3:

Demonstration of the overall value chain

(Neustark, Kästli, Ara Region Bern, Empa) (Month 6-21)

Task 4:

Life Cycle Assessment – evaluation of the environmental performance of the overall value chain (PSI, Neustark, Kästli, Ara Region Bern, Empa) (Month 3-24)

Task 5:

End-of-demonstration evaluation of the overall value chain

(Neustark, Kästli, Ara Region Bern, Empa, PSI) (Month 22-24)